Wood Preservation

Our woods are pre-treated with the state-of-the-art TANALITH preservative to ensure a long life and require little maintenance.

Proven long-term protection

More than 20 years of successful commercial use, and extensive independent testing, underpin the performance of the latest Tanalith® wood preservative and Tanalith® pressure-treated wood.

Protecting against all forms of wood rot and insect attack, including termites, this proven treatment incorporates exclusive, award-winning BARamine® application technologies that help deliver an even deeper preserving action on woods.

Treated woods have an initial pale green color that slowly changes to a honey brown and, eventually, to a natural silvery gray.

As an alternative, we can also incorporate the TANATONE™ color technology into the treatment, which provides an intense brown color to treated wood.

We sell the following treated products:

- Lumber

- Poles for airline

- Poles for fencing and agriculture

- Pine bark

- Pallets

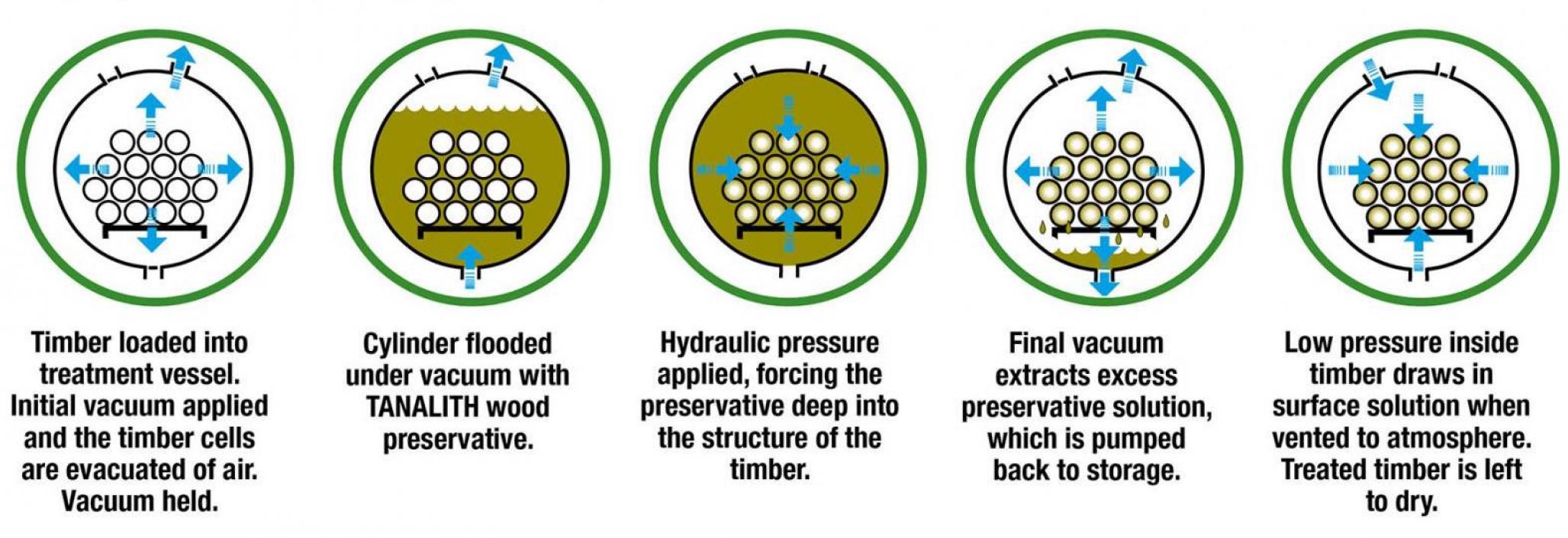

High pressure treatment process

-

The woods are loaded into the treatment container. An initial vacuum is applied and the wood cells are emptied of air.

-

The treatment vessel is flooded under vacuum with Tanalith® wood preservative and, if required, with TANATONE™ coloring agent.

-

Hydraulic pressure is applied, forcing the preservative to penetrate deep into the wood structure.

-

A final vacuum extracts any excess preservative solution, which is pumped back into the tank.

-

The low pressure inside the wood extracts a surface preservative solution when released into the atmosphere. The treated woods are left to dry.